Industry News

-

The difference between lead-free reflow and leaded reflow

Lead-free reflow soldering is because the solder paste used is lead-free environmentally friendly solder paste, and the products are lead-free environmentally friendly products. There are some differences between lead-free reflow and general lead reflow, and JEENOCE shares the main differences below.

News Center / Industry News / 2022-09-12 15:46:31

1, the welding temperature is different: lead-free reflow welding temperature is high, and lead reflow welding temperature is low.

2, environmental protection is different: lead-free reflow environmental protection does not prohibit lead products, must be lead-free environmental protection products.

3. Different high temperature resistance: the high temperature resistance of lead-free reflow welding is better than that of lead reflow welding.

4, the lead solder alloy has low melting point, low welding temperature, less thermal damage to electronic products; The wetting Angle of lead solder alloy is small, the weldability is good, and the possibility of "false welding" of product solder joint is small; The toughness of the solder alloy is good, and the vibration resistance of the solder joint formed is better than that of the lead-free solder joint.

Lead-free reflow welding machine belongs to one kind of reflow welding. Early reflow solders were made of lead-based materials. With the deepening of environmental protection, people pay more and more attention to lead-free technology (that is, today's lead-free reflow welding). The biggest change is in the material, especially the solder. In terms of process, the biggest impact is the welding process. This is mainly caused by the characteristics of the solder alloy and the corresponding flux. -

SMT reflow process optimization and equipment maintenance

SMT reflow soldering process is to achieve the mechanical and electrical connection between the solder end or pin of the surface-assembled component and the printed board solder pad by re-melting the paste soft solder material pre-allocated to the printed board pad. The advantages of this process are that the temperature is easier to control, oxidation can be avoided during welding, and the cost of manufacturing products is also easier to control. JEENOCE introduces SMT reflow process optimization and equipment maintenance.

News Center / Industry News / 2023-02-08 15:46:31

First, good quality SMT reflow welding production process optimization method

1. To set a scientific SMT processing reflow temperature curve and regularly do real-time testing of the temperature curve.

2. Welding should be carried out in accordance with the welding direction of PCB design.

3. The conveyor belt should be prevented from vibrating during welding.

4. The welding effect of the first printed board must be checked.

5. Whether the welding is sufficient, whether the surface of the solder joint is smooth, whether the shape of the solder joint is half moon, the situation of the tin ball and the residue, the situation of continuous welding and virtual welding. Also check the PCB surface color changes and other conditions. And adjust the temperature curve according to the inspection results. The welding quality should be checked regularly during the whole batch production process.

6. Regular maintenance of SMT reflow welding, due to long-term work of the machine, attached to solidified rosin and other organic or inorganic pollutants, in order to prevent PCB secondary pollution and ensure the smooth implementation of the process, it is necessary to conduct regular maintenance and cleaning.

Second, SMT reflow equipment maintenance operation precautions

1. Need to develop SMT processing reflow equipment maintenance system, we must do equipment maintenance after the use of SMT processing reflow, otherwise it is difficult to maintain the service life of the equipment.

2. Daily inspection and maintenance of each component should be carried out, paying special attention to the transmission network belt, which can not be stuck or fall off;

3. When repairing the machine, the power supply should be shut off to prevent electric shock or short circuit;

4. The machine must be stable and not inclined or unstable;

5. Regularly clean the furnace, mesh belt and condenser for SMT reflow welding, and make weekly, monthly and quarterly maintenance plans to ensure SMT reflow welding quality. -

Analysis of the basic principle of reflow welding

The principle of reflow welding is very simple, that is, put an appropriate amount of solder on the circuit board welding site in advance, and then mount the surface assembly components, and then use the external heat source to make the solder flow again to welding a welding process, the heating process of reflow welding can be divided into preheating, insulation, welding and cooling four temperature zones, there are two main methods of realization: One is to pass the circuit board through the four temperature areas in the furnace sequentially along the direction of the transmission system; The other is to park the circuit board in a fixed position, and under the action of the control system, adjust and control the temperature change according to the gradient law of the four temperature regions. In fact, we can better grasp the principle of reflow soldering by understanding the internal structure of the reflow welding machine.

News Center / Industry News / 2022-09-12 15:46:31

Reflow welding machine structure:

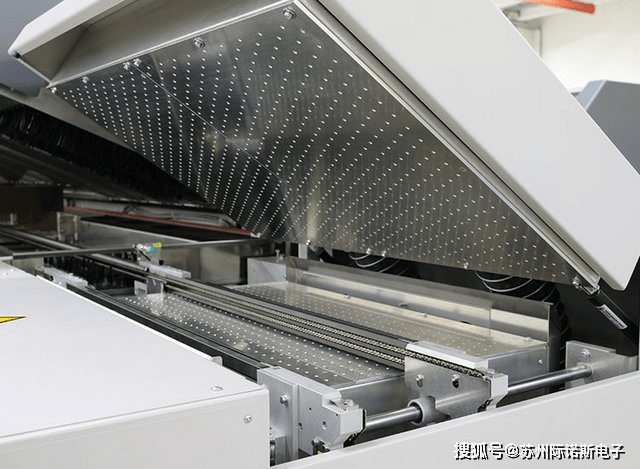

Reflow welding machine is mainly composed of four parts: transmission system, control system, heating system and cooling system. Due to the different way of heating, the internal composition structure will be different, below we take the heat division reflow welding machine as an example:

(1) Transmission system: the transmission system mainly has two types of mesh belt and chain type, wherein the mesh belt transmission can be arbitrarily placed printed board, suitable for single-panel welding, it overcomes the defects of printed board heating may cause depression, but the use of dual panel welding and equipment wiring has limitations; Chain transmission is to place the PCB on the stainless steel chain extension pin for transmission, and the chain width can be adjusted to meet the requirements of different printed board widths, but it may cause depression after heating for wide or ultra-thin printed boards.

(2) Control system: Control system is the center of reflow welding machine, its mode of operation, flexibility and functions have a direct impact on the use of equipment, advanced reflow welding equipment has all adopted the computer or PLC control mode, the use of computer rich hardware and software resources to greatly enrich and improve the reflow welding equipment functions, effectively ensure the improvement of production management quality.

(3) Heating system: each temperature zone of the heating system adopts forced independent circulation, independent control, and upper and lower heating mode, so that the temperature of the furnace chamber is accurate, uniform and the heat capacity is large. Among them, the temperature controller maintains the temperature at the set value through PID control, and the temperature sensor adopts thermocouple to measure the temperature of the air flow.

(4) Cooling system: The cooling system mainly has two kinds of heat exchanger cooling and fan cooling, and the PCB must be cooled immediately after reflow welding to get a good welding effect. Because the flux is easy to condense in the cooling system, it is necessary to check and clean the flux on the flux filter regularly, otherwise the decrease in the efficiency of the thermal cycle will reduce the efficiency of the cooling system, make the cooling worse, and lead to the deterioration of the welding quality of the product. -

Reflow Furnace Market Research Report 2023

Reflow furnace market report by analyzing the global and Chinese market operation situation (political and legal environment, economic environment, social environment and technical environment), combined with the overall overview of the industry, upstream and downstream industries, product types and application field market segment development, summarized the reflow furnace industry market development trend in the past few years and the current industry development trend. And focus on the future development trend of the industry to make predictions.

News Center / Industry News / 2023-02-08 15:46:31

According to the reflow furnace market research report, in 2021, the global reflow furnace market size reached 1.989 billion yuan (RMB), and the market size of China's reflow furnace reached, and the report also gave the import and export amount of China's reflow furnace in 2021. The report predicts that by 2027, the global reflow furnace market will reach 2.882 billion yuan, and will reach a compound annual growth rate of 6.38% during the forecast period.

Report publisher: Hunan Beez Information Consulting Co., LTD

Reflow Furnace Industry report is a global and China reflow furnace industry development overview analysis, including the reflow furnace industry development stage, market size, market share and market concentration analysis. At the same time, the report also analyzes the competitive landscape of reflow furnace industry in detail to help enterprises clear market positioning and formulate the right development strategy.

Summary of each chapter of the catalog:

Chapter 1: This chapter introduces the definition and characteristics of reflow furnace industry, upstream and downstream industries, driving factors and limiting factors affecting the development of reflow furnace industry;

Chapter 2: This chapter analyzes the macro environment of the global and Chinese industries, and uses PEST analysis model to explain the development environment of the global and Chinese markets one by one;

Chapter 3 and 4: Analysis of global and Chinese reflow furnace industry development overview (development stage, market size, competition pattern, market concentration);

Chapter 5 and 6: This chapter explains the global market analysis of North America, Europe, Asia Pacific, and major countries in these regions. The sixth chapter analyzes the output and output value of reflow furnace industry in different regions of the world.

Chapter 7, 8: The two chapters of reflow furnace industry product types and subdivision application market share and scale are listed and analyzed and market segmentation forecast;

Chapter 9 and 10: Chapter 9 details the main enterprises, basic information, introduction of main products and services, business overview (sales, product sales, gross margin, price), and SWOT analysis in China reflow furnace industry, and chapter 10 is the analysis of industry competition strategy;

Chapter 11, 12: The two chapters include the forecast of the global, North America, Europe, Asia Pacific, and other regions of the reflow furnace industry market size and China's reflow furnace industry market development trend and key technology development trend;

Chapter 13: Growth, return cycle, risk and hot spots analysis of reflow furnace industry.

List of major competitors:

ERSA

HELLER

BTU

JT

Dongguan Pengyi Electronics

ShenZhen Leadsmt

By product:

7 zone reflow system

10-zone reflow soldering system

12 zone reflow system

other

By application field:

Medical electronics

Consumer electronics

Automotive electronics

other

The reflow Furnace Market analysis report provides a detailed analysis of the global and China reflow furnace industry development stage, competitive landscape, regional market overview and status quo, and market size. Secondly, the report also details the key policies of the reflow furnace industry in the world (North America, Europe, Asia Pacific), and analyzes the sales volume, sales volume and growth rate of the reflow furnace market in major countries in each region.

catalogue

The first chapter is the basic overview of reflow furnace industry

1.1 Reflow furnace industry definition and characteristics

1.1.1 Introduction to reflow furnace industry

1.1.2 Reflow furnace industry characteristics

1.2 Analysis of global and Chinese reflow furnace industry chain

1.2.1 Global and China reflow furnace industry upstream industry introduction

1.2.2 Analysis of downstream industries of global and Chinese reflow furnace industry

1.3 Subdivision of reflow furnace industry types

1.3.1 Zone 7 reflow system

1.3.2 Zone 10 reflow system

1.3.3 Zone 12 reflow system

1.3.4 Others

1.4 Subdivision of reflow furnace industry application field

1.4.1 Medical Electronics

1.4.2 Consumer Electronics

1.4.3 Automotive electronics

1.4.4 Others

1.5 Global and Chinese reflow furnace industry development driving factors

1.6 Global and China reflow furnace industry development constraints

The second chapter analyzes the market operation situation of reflow furnace industry in the world and China

2.1 Global and Chinese reflow furnace industry policy and regulatory environment analysis

2.1.1 Major policy and regulatory environments in the global and Chinese industries

2.1.2 Global and Chinese industry-related development plans

2.2 Analysis of economic environment of reflow furnace industry in the world and China

2.2.1 Analysis of global macroeconomic situation

2.2.2 Analysis of China's macroeconomic situation

2.2.3 Analysis of industrial macroeconomic environment

2.2.4 Status and role of reflow furnace industry in national economy

2.3 Social environment analysis of reflow furnace industry

2.4 Technical environment analysis of reflow furnace industry

Chapter three global reflow furnace industry development overview analysis

3.1 Global reflow furnace industry development status

3.1.1 Global reflow furnace industry development stage

3.2 Market size of reflow furnace industry by region of the world

3.3 Global reflow furnace industry competition pattern

3.4 Market concentration analysis of global reflow furnace industry

3.5 The impact of COVID-19 on the global reflow furnace industry

Chapter IV Analysis of the development of reflow furnace industry in China

4.1 Development status of reflow furnace industry in China

4.1.1 Development stage of reflow furnace industry in China

4.1.2 "14th Five-Year Plan" policy guidance on reflow furnace industry

4.2 Development opportunities and challenges of reflow furnace industry in China

4.3 Impact of COVID-19 on reflow furnace industry in China

4.4 Impact of "carbon neutral" policy on reflow furnace industry

The fifth chapter is a detailed analysis of the reflow furnace industry market in various regions of the world

5.1 Overview of reflow furnace industry development in North America

5.1.1 Development status of reflow furnace industry in North America

5.1.2 Main policies of reflow furnace industry in North America

5.1.3 Market analysis of reflow furnaces in major North American countries

5.1.3.1 US reflow furnace market sales volume, sales volume and growth rate

5.1.3.2 Canadian reflow furnace market volume, sales and growth rate

5.1.3.3 Sales volume, sales volume and growth rate of reflow furnace market in Mexico

5.2 Overview of reflow furnace industry development in Europe

5.2.1 Development status of reflow furnace industry in Europe

5.2.2 Main policies of reflow furnace industry in Europe

5.2.3 Market analysis of reflow furnaces in major European countries

5.2.3.1 German Reflow furnace market volume, sales and growth rate

5.2.3.2 UK Reflow Furnace market volume, value and growth rate

5.2.3.3 Volume, value and growth rate of reflow furnace market in France

5.2.3.4 Volume, value and growth rate of Reflow furnace market in Italy

5.2.3.5 Nordic Reflow Furnace market volume, value and growth rate

5.2.3.6 Volume, value and growth rate of Reflow furnace market in Spain

5.2.3.7 Volume, value and growth rate of Reflow furnace market in Belgium

5.2.3.8 Volume, value and growth rate of Reflow furnace market in Poland

5.2.3.9 Volume, sales and growth rate of reflow furnace market in Russia

5.2.3.10 Turkey Reflow furnace market volume, sales and growth rate

5.3 Overview of reflow furnace industry development in the Asia-Pacific region

5.3.1 Development status of reflow furnace industry in the Asia-Pacific region

5.3.2 Main policies of reflow furnace industry in Asia Pacific region

5.3.3 Analysis of reflow furnace market in major Asia-Pacific countries

5.3.3.1 Sales volume, sales and growth rate of reflow furnace market in China

5.3.3.2 Japan reflow furnace market sales volume, sales volume and growth rate

5.3.3.3 Volume, value and growth rate of reflow furnace market in Australia and New Zealand

5.3.3.4 Volume, sales and growth rate of reflow furnace market in India

5.3.3.5 ASEAN Reflow Furnace market volume, sales and growth rate

5.3.3.6 Sales volume, sales volume and growth rate of South Korea reflow furnace market

Chapter 6 Analysis of the output and output value of reflow furnace industry in different regions of the world

6.1 Analysis of production and output value of reflow furnace industry in North America

6.2 Analysis of output and output value of reflow furnace industry in Europe

6.3 Analysis of production and output value of reflow furnace industry in Asia Pacific region

6.4 Analysis of output and output value of reflow furnace industry in other regions

Chapter 7: Global and China reflow furnace industry product category market size and forecast

7.1 Product categories and market size of global reflow furnace industry

7.1.1 Sales volume and market share of global Reflow furnace industry products by category (2017-2028)

7.1.2 Sales and market Share of global Reflow furnace industry products by category (2017-2028)

7.2 Market share of reflow furnace industry in China by product category

7.2.1 Sales volume and market share of Reflow furnace industry products in China by category (2017-2028)

7.2.2 Sales and market share of Reflow furnace industry products in China by category (2017-2028)

7.3 Product price trends of reflow furnace industry in the world and China

7.4 Global factors affecting product price fluctuations in reflow furnace industry

7.4.1 Cost

7.4.2 Supply and demand

7.4.3 Associating Products with Products

7.4.4 Others

7.5 Analysis of advantages and disadvantages of various types of products in the global reflow furnace industry

Chapter 8 Analysis and forecast of global and Chinese reflow furnace industry application market

8.1 Global reflow furnace industry application market size

8.1.1 Sales volume and market share of major terminal applications in the global Reflow Furnace market (2017-2028)

8.1.2 Sales of major terminal applications in the global Reflow furnace market (2017-2028)

8.2 Market share of reflow furnace industry application field in China

8.2.1 Market share of reflow furnaces in different application fields in China in 2018

8.2.2 Market share of reflow furnaces in different application fields in China in 2022

8.3 Import and export analysis of reflow furnace industry in China

8.4 Focus analysis of reflow furnace products in different application fields

8.5 Influence of development of downstream application industries on reflow furnace industry

Chapter 9 Analysis of major enterprises in reflow furnace industry in the world and China

9.1 HELLER

9.1.1 HELLER Basic Information

9.1.2 Introduction of HELLER's main products and services

9.1.3 HELLER's operation analysis (sales, product sales, gross profit margin, price)

9.1.4 HELLERSWOT analysis

9.2 ERSA

9.2.1 ERSA Basic Information

9.2.2 Introduction of ERSA's main products and services

9.2.3 ERSA operation analysis (sales, product sales, gross profit margin, price)

9.2.4 ERSASWOT Analysis

9.3 BTU

9.3.1 BTU Basic Information

9.3.2 Introduction of BTU's main products and services

9.3.3 BTU operation analysis (sales, product sales, gross profit margin, price)

9.3.4 BTUSWOT Analysis

9.4 JT

9.4.1 JT Basic Information

9.4.2 Introduction of JT main products and services

9.4.3 JT operation analysis (sales, product sales, gross profit margin, price)

9.4.4 JTSWOT analysis

9.5 Dongguan Pengyi Electronics

9.5.1 Dongguan Pengyi Electronics Basic information

9.5.2 Introduction of Dongguan Pengyi Electronics' main products and services

9.5.3 Operating situation analysis of Dongguan Pengyi Electronics (sales volume, product sales volume, gross profit margin, price)

9.5.4 Dongguan Pengyi Electronic SWOT analysis

9.6 ShenZhen Leadsmt

9.6.1 ShenZhen Leadsmt Basic Information

9.6.2 ShenZhen Leadsmt's main products and services

9.6.3 ShenZhen Leadsmt Business Situation Analysis (sales, product sales, gross profit margin, price)

9.6.4 ShenZhen LeadsmtSWOT Analysis

Chapter 10 Competition strategy analysis of reflow furnace industry

10.1 Competition among existing enterprises in reflow furnace industry

10.2 Analysis of potential entrants in reflow furnace industry

10.3 Threat analysis of reflow furnace industry substitutes

10.4 Bargaining power of reflow furnace industry suppliers and customers

Chapter 11 Global reflow furnace industry market size forecast

11.1 Global reflow furnace industry market size forecast

11.2 Forecast of market size of reflow furnace industry in North America

11.3 Market size forecast of reflow furnace industry in Europe

11.4 Forecast of market size of reflow furnace industry in Asia Pacific

11.5 Forecast of market size of reflow furnace industry in other regions

Chapter 12 Development prospect and trend of reflow furnace industry in China

12.1 Market development trend of reflow furnace industry in China

12.2 Development trend of key technologies in reflow furnace industry in China

Chapter 13: Evaluation of investment value of reflow furnace industry

13.1 Growth analysis of reflow furnace industry

13.2 Analysis of return on investment cycle in reflow furnace industry

13.3 Investment risk analysis of reflow furnace industry

13.4 Analysis of hot investment in reflow furnace industry

Reflow furnace market report from the market macro environment, development trend, competitive situation, potential opportunities and risks and other aspects of research and analysis, through valuable market insight to help target users to enhance the core competitiveness of enterprises. -

SMT reflow welding introduction

Reflow refers to the soldering of mechanical and electrical connections between the solder ends or pins of surface-assembled components and the printed board solder pad by remelting the paste solder preallocated to the printed board pad. It provides a heating environment to melt the solder paste so that the surface mount components and PCB solder pad can be reliably combined together through the solder paste alloy. According to the technical characteristics of reflow welding, it is divided into gas phase reflow, infrared reflow and hot air reflow. The current mainstream equipment adopts hot air reflow. Hot air reflux is the use of hot air flow to make the colloidal flux (solder paste) in a certain high temperature air flow to achieve SMD welding, because this hot air flow is circulating inside the welding machine to achieve welding purposes, so, In the industry, this equipment that uses the principle of thermal Reflow to achieve surface mount components welding is called Reflow Machine.

News Center / Industry News / 2022-09-12 15:46:31

The Reflow device is usually placed at the back end of the SMT device to complete the welding of the patch components. After nearly ten years of development, reflow welding equipment has developed from a relatively simple thermal processing equipment to a PC as a human-machine dialogue window, and a higher automation program for the production process formula. The control system of the equipment has also changed from a simple electrical control to a system integration solution with PC as the operating platform and PLC as the system control core to adapt to the increasingly complex production welding process. With the arrival of lead-free welding, rib flux recovery and energy saving and environmental protection, higher requirements will be put forward for the automation and intelligent control of equipment.